Why choose our services ?

National NDT Services prides itself on its commitment to continuously update, incorporate and utilize modern technology and methods both with respect to staff and equipment in order to remain competitive and effective in the market. The company has thus grown to become one of the leading local companies in the Supply of non-destructive testing services.- ULTRASONIC TESTING

- PAINT THICKNESS TESTING

- HARDNESS TESTING

- MAGNETIC PARTICLE TESTING

- SPARK / HOLIDAY DETECTION

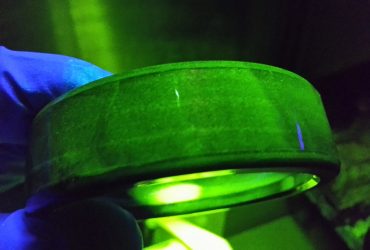

- DYE PENETRANT TESTING

- POSITIVE MATERIAL IDENTIFICATION (PMI)

- INDUSTRIAL GAMMA AND XRAY RADIOGRAPHY